Innovation in skiing

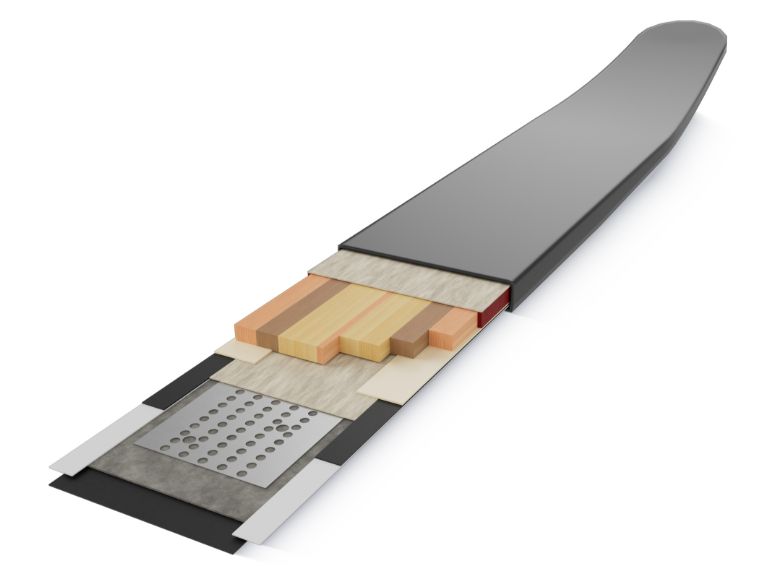

SKI technologySkis are sophisticated sports equipment designed for optimum performance and safety on the snow. They are subject to extreme forces during use and must therefore be both stable and flexible. To meet these requirements, a ski consists of several layers of different materials, each of which has specific properties.

Typical layer structure of a ski

Different types of wood such as beech or bamboo often form the basic structure of the ski. These woods are known for their robustness and elasticity, which helps them to absorb the forces of skiing and provide good basic flexibility. Plastics and carbon are also used. These materials are light and strong, which contributes to the overall stability of the ski without significantly increasing its weight. Glass fibers are also used to provide additional strength and flexibility.

Metal straps are another component in the construction of a ski. Steel, stainless steel or aluminum are used to give the skis the necessary resistance and rigidity under enormous loads. ACP straps therefore make a decisive contribution to the safety and performance of modern skis.

ACP is an official partner of the DSV

Top performance on the slopesAs the official partner of the German National Alpine Ski Team, ACP supplies cutting-edge technology for top athletes: our scaffolding tapes. Developed from decades of experience in metal processing, our scaffolding tapes set standards:

- Excellent adhesion properties

- Efficient production process

- Resource-saving processing

- Maximum safety for recreational athletes and professionals

Certified QUality

We deliver

Advantages of ACP webbing

Performance through experienceThanks to decades of experience in the coating and processing of metal straps, ACP can offer skiing a unique product that is characterized above all by its excellent adhesion properties between the strap and the surrounding layers of the ski. The pre-treated and coated ACP belts eliminate costly and energy-intensive production steps for the customer, allowing them to focus on the actual ski construction. This increase in efficiency contributes to sustainability, as fewer resources are consumed and the ecological footprint of the production process is improved at the same time.

The use of ACP webbing is therefore an example of the constant further development of ski technology. More and more manufacturers are using this technology to increase the performance of their skis. In combination with the other materials, the result is a piece of sports equipment that offers a high level of comfort and maximum safety for both recreational skiers and professional athletes.

our value chain in metal processing

Everything from a single sourceWith over 800 employees at 14 production sites worldwide, the HUEHOCO Group offers cross-industry system solutions through the cooperation of all our companies. The product portfolio ranges from the manufacture of cold-rolled strip to the development and production of various coating systems and coil coating itself, right through to roll cutting and punching processes and the manufacture of parts in punched or progressive laminates.

Get in touch with us

Goals, plans, questions, wishes?