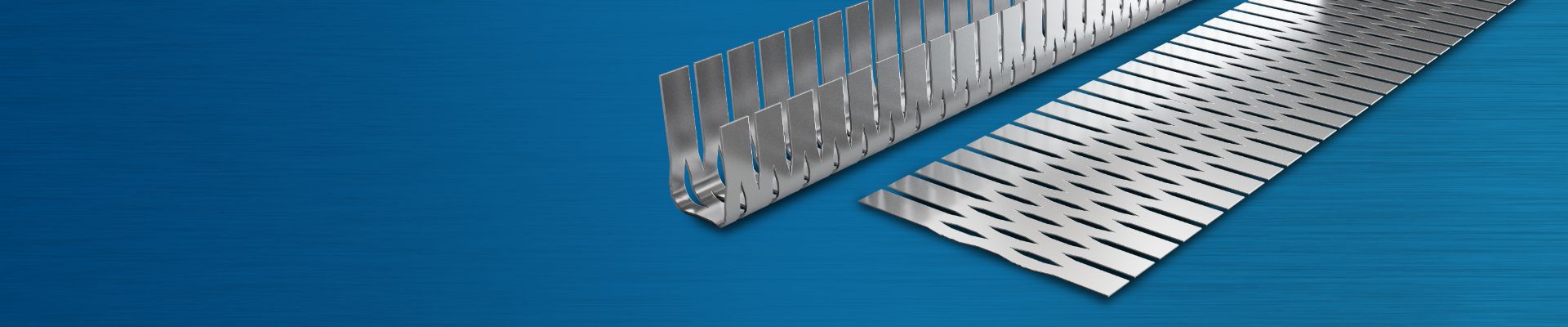

We manufacture over 400 different types and designs of endless roll-cut metal straps, also known as roll-cut straps or scaffolding straps. These slitter belts or scaffolding belts are used in a wide variety of applications – from automotive, wind turbines and the electrical industry to leisure and sports articles.

ACP roll slitters are characterized by their enormous accuracy of fit and long running lengths. Another advantage of roll-cut metal strips is the high production speed compared to punched metal strips. In addition, this manufacturing process is a waste-free finishing process, which makes the slitter belts particularly sustainable and also allows them to be produced more economically.

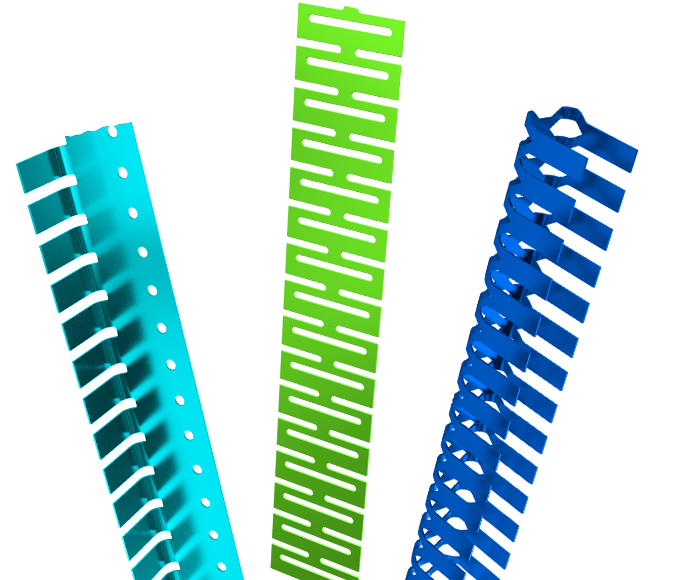

DESIGNS AND GEOMETRIES

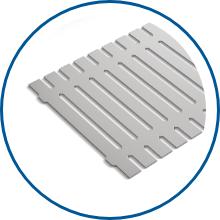

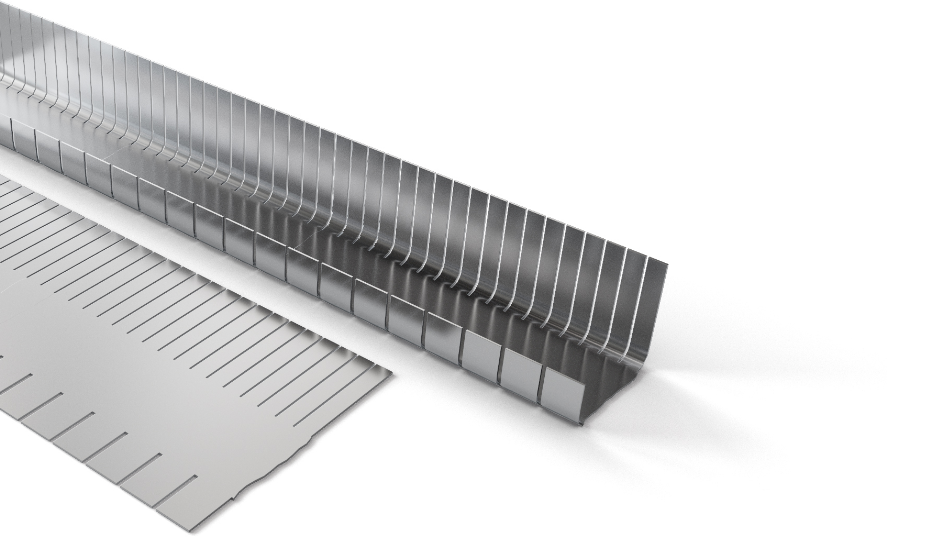

“SINGLE TRACK” design

Roll-cut metal stripsWith this type of stand belt, the stretching in the belt is generated via a rolling track. The width of the rolling track and the stretching can be variably selected. These tapes are characterized by high stability and rigidity and are therefore used in static seals such as window shaft seals. However, the single-web, breakable steel belts can also be found in the non-automotive sector as PVC edge protection profiles. Like all our solutions, this belt can also be produced coated or uncoated.

BASIC MATERIALS

- Metal types: steel, stainless steel, aluminum alloys, non-ferrous metals

- Belt widths from 10-80 mm possible

- Tape thicknesses of the carrier material from 0.20-0.80 mm possible

- Running length up to 40,000 meters per spool

INDIVIDUAL PRESENTATION

Of course, we can supply you with the endless roll cutting tapes in the packaging you require. Whether individual cores or complete winding frames – we adapt to your technical requirements.

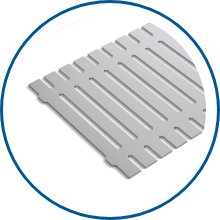

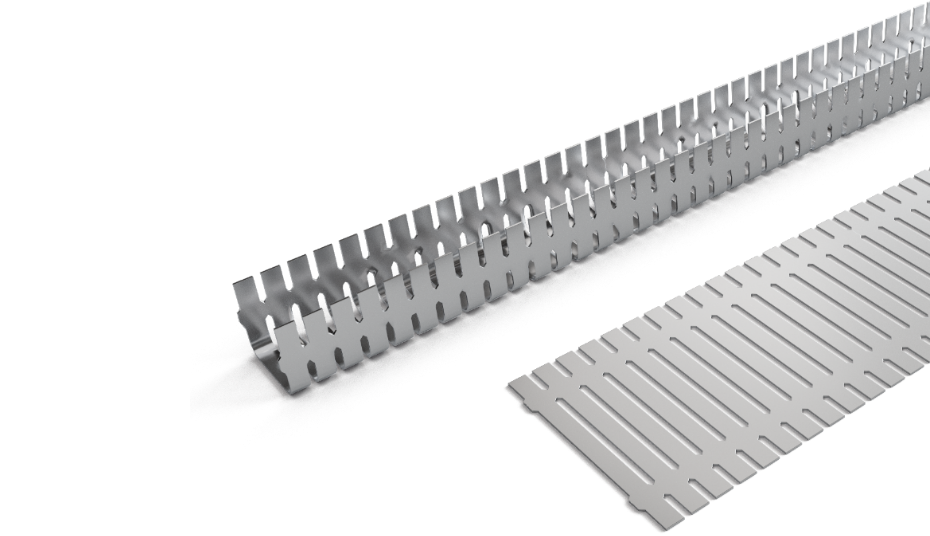

“Double TRACK” design

Roll-cut metal stripsThe double-track tapes are also rolled out. Due to their higher elongation and narrow webs, these belts are flexible and are used in dynamic seals. These tapes can also be offered as a breakable variant, which results in maximum flexibility in the sealing profile. Like all our solutions, this belt can also be produced coated or uncoated.

BASIC MATERIALS

- Metal types: steel, stainless steel, aluminum alloys, non-ferrous metals

- Belt widths from 10-80 mm possible

- Tape thicknesses of the carrier material from 0.20-0.80 mm possible

- Running length up to 40,000 meters per spool

INDIVIDUAL PRESENTATION

Of course, we can supply you with the endless roll cutting tapes in the packaging you require. Whether individual cores or complete winding frames – we adapt to your technical requirements.

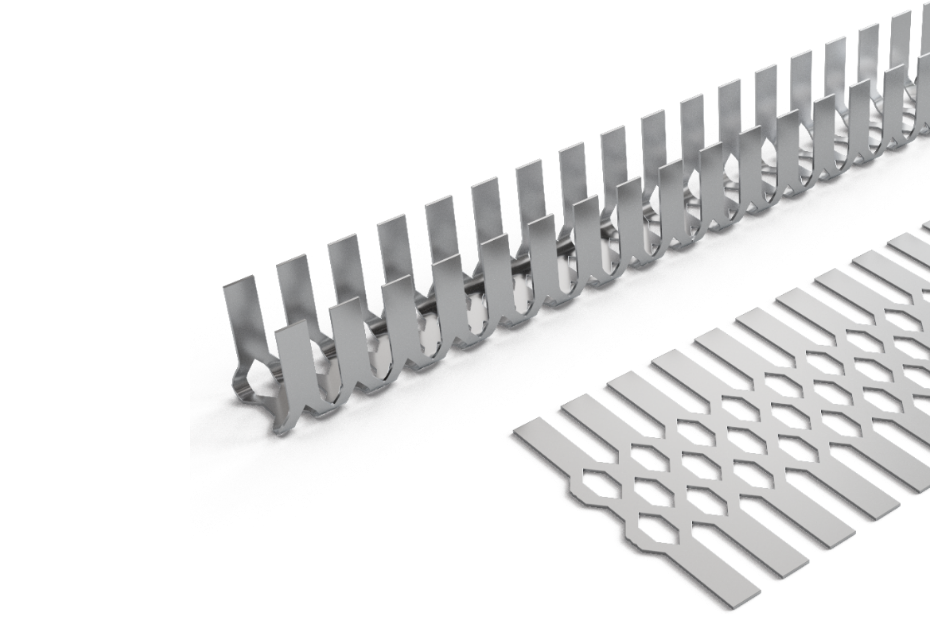

“flex carrier” DESIGN

Roll-cut metal stripsA high degree of flexibility, clamping force and stability make the Flex Carrier a carrier material for a wide range of applications, for example for trunk, door or hood seals. Classic flex belts with medium elongation and a slat width > 3 mm hardly show any “hungry horse” effect. Highly elongated flex belts with single or multi-webbed internal geometries and slats with a width of 3 mm and material thicknesses of < 0.45 mm are cost-efficient and variable in design according to customer requirements. Like all our solutions, this belt can also be produced coated or uncoated.

BASIC MATERIALS

- Metal types: steel, stainless steel, aluminum alloys, non-ferrous metals

- Belt widths from 10-80 mm possible

- Tape thicknesses of the carrier material from 0.20-0.80 mm possible

- Running length up to 40,000 meters per spool

INDIVIDUAL PRESENTATION

Of course, we can supply you with the endless roll cutting tapes in the packaging you require. Whether individual cores or complete winding frames – we adapt to your technical requirements.

“DIAMOND Carrier” design

Roll-cut metal stripsThe “Diamond Carrier” design is characterized by high tensile strength and rigidity. It is a very frequently used form because it is very light, inexpensive and stable.

BASIC MATERIALS

- Metal types: steel, stainless steel, aluminum alloys, non-ferrous metals

- Belt widths from 10-80 mm possible

- Tape thicknesses of the carrier material from 0.20-0.80 mm possible

- Running length up to 40,000 meters per spool

INDIVIDUAL PRESENTATION

Of course, we can supply you with the endless roll cutting tapes in the packaging you require. Whether individual cores or complete winding frames – we adapt to your technical requirements.

“Stagger carrier” DESIGN

Roll-cut metal stripsThe advantage of the stagger carrier is that this cut shape is flexible in all directions and can be shaped around several axes. The optimum solution for difficult shoring situations. Like all our solutions, this belt can also be produced coated or uncoated.

BASIC MATERIALS

- Metal types: steel, stainless steel, aluminum alloys, non-ferrous metals

- Belt widths from 10-80 mm possible

- Tape thicknesses of the carrier material from 0.20-0.80 mm possible

- Running length up to 40,000 meters per spool

INDIVIDUAL PRESENTATION

Of course, we can supply you with the endless roll cutting tapes in the packaging you require. Whether individual cores or complete winding frames – we adapt to your technical requirements.

It’s the COATING that counts

More than a roll cutterSlitter belts are usually combined with other materials in further processing and require certain physical properties. This often requires various technical coatings.

ACP offers a wide range of technical coatings for all products

TECHNICAL COATINGS:

- Non-stick lacquer coatings

- Anti-slip lacquer coatings

- Coatings with bonded coating

- Coatings with high-temperature paints

- Coatings with liquid rubber

- Coatings with foamed and non-foamed rubber

THERMOREACTIVE ADHESION PROMOTER

FOR rubber:

- Natural rubber (NR)

- Polyisoprene (IR)

- Butadiene styrene (SBR)

- Polybutadiene (BR)

- Polychloroprene (CR)

- Butyl (IIR)

- Ethylene propylene (EPDM)

- Chlorosulfonated polyethylene (CSM)

THERMOREACTIVE ADHESION PROMOTER

FOR PLASTICS:

- Polycarbonate

- Polyvinyl chloride (PVC)

- Acrylonitrile butadiene styrene (ABS)

- Cellulose acetobutyrate (CAB)

- Polypropylene (PP)

- Thermoplastic polyurethane (TPU)

- Polyamide (PA)

- Polyolefinic or other thermoplastics

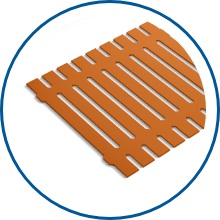

We bring color into play

Decorative coatingsNormally, the roll-cut metal strips are installed in such a way that a colored effect makes no sense at first. However, color coding can be useful as a distinguishing feature for very similar components, such as seals.

Another idea is to process colored roll cutting tapes in transparent plastics. This can result in interesting products with a very technical look.

Do you have an application? We deliver the implementation.

Get in touch with us

Goals, plans, questions, wishes?